As of 2022, the mining market was worth just over $28 billion, with estimates forecasting approximately a 12% increase by 2030.

As the mining industry continues to grow, competition will continue to grow as well. Companies wanting to stay competitive or reduce associated costs related to daily operations and risks should adopt IoT in mining solutions that enhance site and worker safety, improve labor productivity, and effectively monitor equipment.

How is IoT Used in the Mining Industry?

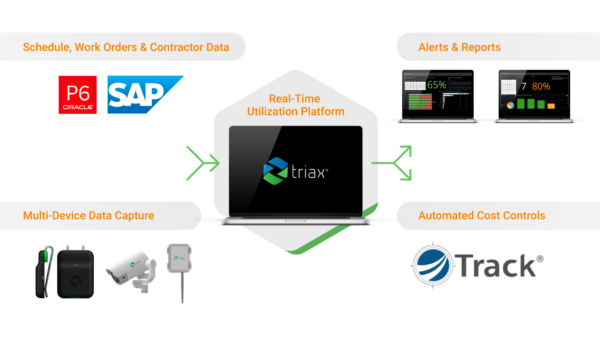

IIoT, or the Industrial Internet of Things, is a digital solution for companies needing to integrate the latest software and tech devices into their daily workflows and business operations. These integrations allow the company to increase safety, reduce downtime and risks, and improve productivity and communications.

In the mining industry, companies typically have several large worksites, with thousands of workers and equipment resources at each of them.

Effectively keeping track of so many different equipment and labor resources is nearly impossible without the right monitoring tools in place, and a lack of effective monitoring can lead to increased worker safety hazards and inefficient equipment utilization.

Having effective, quick-response safety measures and real-time labor and equipment monitoring is crucial for an efficient work site. With IoT in mining technology, it’s easier than ever to track equipment, stay on top of worker productivity, and enable greater site and worker safety.

For example, software such as the Spot-r IIoT platform can monitor details such as the following:

- Flow rates

- Pressure

- Batteries

- Pumps

- Worker activity

These are just a few of the many areas that can be closely monitored with accuracy with IoT technology.

Use Cases For IoT in Mining

IoT technology is vital in mining projects. Consider these use cases where adopting these technologies helps reduce risks and streamline workflows and performance.

Wearable Technology for Greater Site & Worker Efficiency

Having workers wear advanced wearable IoT technology such as Spot-r can provide management with insights into key worker efficiency metrics such as worker time in a given zone, time on tools, peak operation hours, and more.

This information can empower managers to make cost-saving changes for future shifts and improve labor efficiency and productivity.

Adopting wearable IIoT technology for workers also allows managers to quickly identify where all workers are located on a worksite at any given time, enabling greater site visibility overall. Managers can also be informed about the presence of team members at any given time to assess workforce capabilities clearly.

Software for Increased Labor Productivity

One of the main goals for any industrial business, especially mining, is to increase productivity. This is possible with automation provided by IoT. This integration allows managers to identify productivity in specific zones.

Managers can also assign each worker their own barcodes via the Spot-r system to track their entry and exit for the day. They can also have individual clips that coincide with helmet barcodes to scan in and out of secure access points.

By adopting this solution, managers can reduce the time it takes to check workers in and out and eliminate the foreman needing to track time and reporting hours. Managers also know precisely where each worker depends on their time during the work day and how productive they are during those times. Additionally, a real time alert can be sent if an employee enters an area of the site where they are not supposed to go.

Software for Real-Time Equipment Monitoring

Another use case for IoT in mining is real-time equipment monitoring. Mining worksites often have thousands of equipment resources, and it’s difficult to know how efficiently that equipment is being used.

IIoT technology can provide real-time visibility into which pieces of equipment are being used the most, by whom, and when.

A 24/7 real-time equipment monitoring solution can help maintenance managers uncover and fix hidden costs from underutilized equipment, and prevent over-billing from equipment rental partners.

An equipment monitoring solution can also help maintenance managers identify equipment downtimes and address the cause of equipment downtime quickly. In the long run, this solution helps managers predict and prevent future downtimes, and improves OEE.

Software & Hardware for Improved Worker and Site Safety

Safety is a crucial concern for any mining operation. Real-time monitoring software allows managers to optimize emergency management protocols and tracking. Adopting an IoT safety solution can effectively increase safety and response times.

For instance, if a worker is injured, wearable IIoT technology can drastically reduce response times to help get them to safety and treated immediately. Adopting an IoT solution allows managers to know exactly where workers are located at any given time and call workers to a mustering point should an emergency arise.

Additionally, this technology can alert other workers to potential danger and emergency events to help evacuate or contain situations.

Having this information readily available can help prevent injuries and improve response times drastically when the unexpected occurs. Safety dramatically improves, and management and workers feel more confident and informed while working on a project.

IoT in Mining Devices

The mining industry dramatically benefits from IoT in mining devices. Spot-r IIoT technology provides an integrated suite of worksite management tools such as:

- Spot-r POI tag

- Spot-r EvacTag

- Spot-r EquipTag

Spot-r POI Tag

Spot-r POI tags are mounted in specific locations and are meant to remain in place. They are used to monitor the Spot-r clips that offer insights regarding worker location. This application is ideal for worker authorization protocols and tracking worker activities. Gain more insight into worker activities and location with Spot-r POI Tags.

Spot-r EvacTag

The Spot-r EvacTag provides solutions for evacuations due to emergencies on site. They provide 100-decibel flashing alarms throughout the job site. Improve evacuation times by up to 72% with Spot-r EvacTags. Use them in conjunction with Spot-r POI takes to enhance worker accounting at muster points.

Integrate Spot-r EvacTags to alert crews to evacuate the area during emergency events. Workers can also wear Spot-r Clips to alert management to falls and injuries.

Spot-r EquipTag

Effectively monitor equipment location using the Spot-r EquipTags to track pieces in real time. This rechargeable device is used in conjunction with the Spot-r clips to monitor the proximity of site workers in relation to tagged equipment.

Gain insights about idle time, work times, certification details, and unauthorized operator notifications. Users also have access to utilization history and operator identification. Know where equipment is located and who uses it at all times with Spot-r EquipTags.

See how Triax Technologies Improves Mining Operations

IIoT in the mining industry is essential for today’s operations. Adopting Spot-r technology and software enables you to integrate cutting-edge technology that improves productivity and efficiency on the job site. Spot-R makes it easier to reduce unnecessary expenses and risks while simultaneously streamlining day-to-day operations.

Our full suite of solutions allow site managers to track activities across the site and provide automation to reduce workforce needs while improving accuracy and analytics.

With Spot-R IIoT technology, management and team members have access to communication and insights they need to get the job done efficiently without unnecessary manual checks and notations. Everything related to worker entry, job performance, safety, and location can be accessed directly through a user-friendly dashboard that allows you to generate data and information in real time.

Interested in learning more about Spot-R? Learn more about our IIoT solutions for the mining industry and request a demo of Spot-R today.