Using slap and track devices can determine location and usage with real time data, but could that translate into seven figure savings? That was the question posed by an existing labor productivity and safety client.

Using slap and track devices can determine location and usage with real time data, but could that translate into seven figure savings? That was the question posed by an existing labor productivity and safety client.

Workers who are isolated from other people on a job site—security staff, lone workers, and specialists with jobs in hazardous areas—are especially at risk of injury or sudden accident and represent a challenge to existing safety protocols.

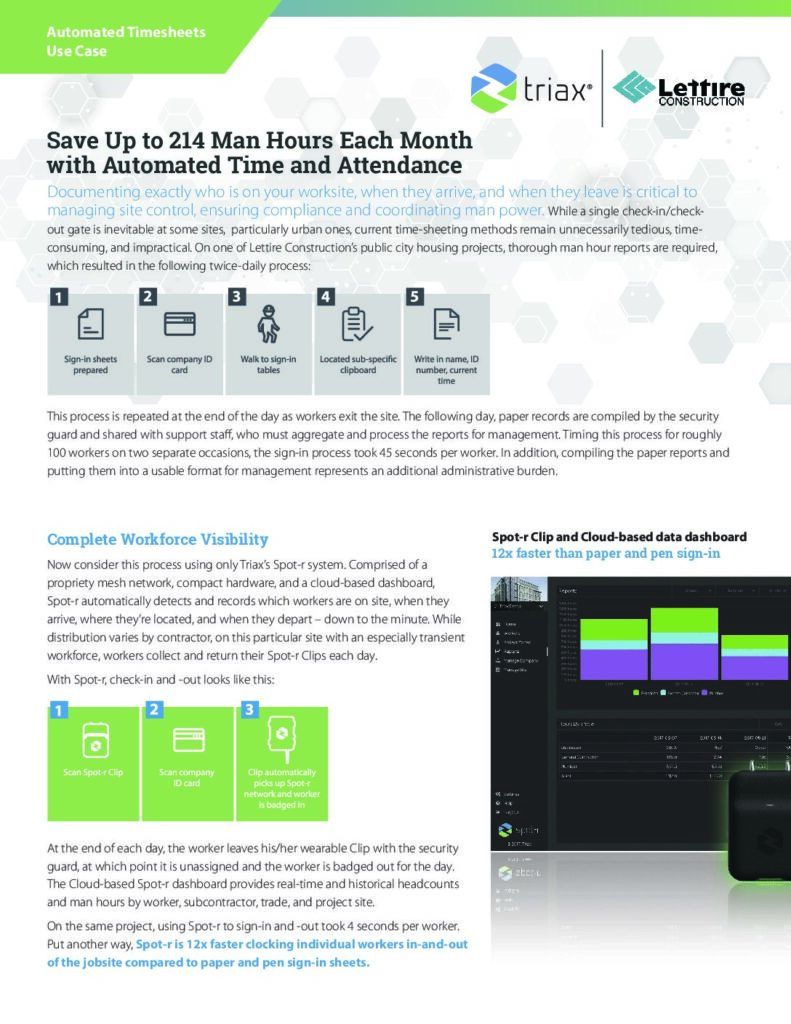

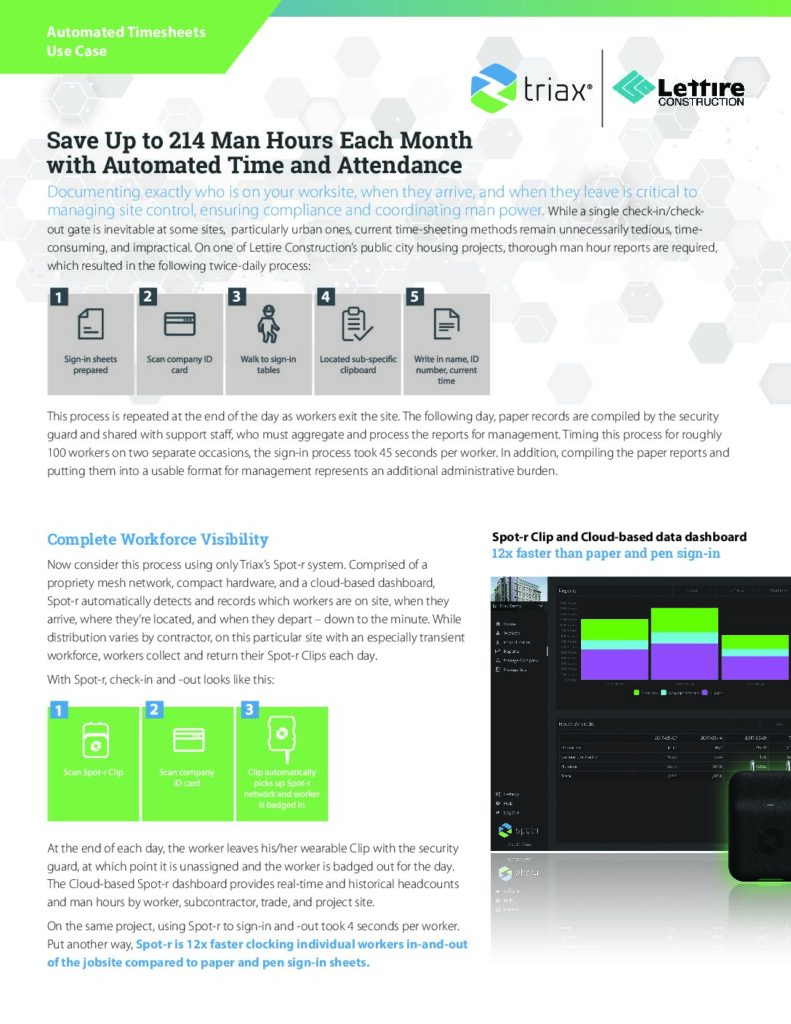

Turnstiles have proven to be an ineffective way to track workers. It does not account for groups in vehicles, missing check-ins, and in the case of shared contractors in divested sites, knowing who exactly is working for what company, what work they’re doing, and if they’re being productive.

Every job site is required to have a plan for how to evacuate in case of emergency & muster all […]

How Spot-r Mesh by Triax® helped one contractor identify ways to increase operational efficiency during a pre-turnaround.

Major turnarounds and planned maintenance events are costly yet critical aspects of keeping energy and industrial facilities operating at maximum […]