Maximize field

productivity & safety

Capture, analyze & act-on field data using our IIoT platform and SaaS analytics

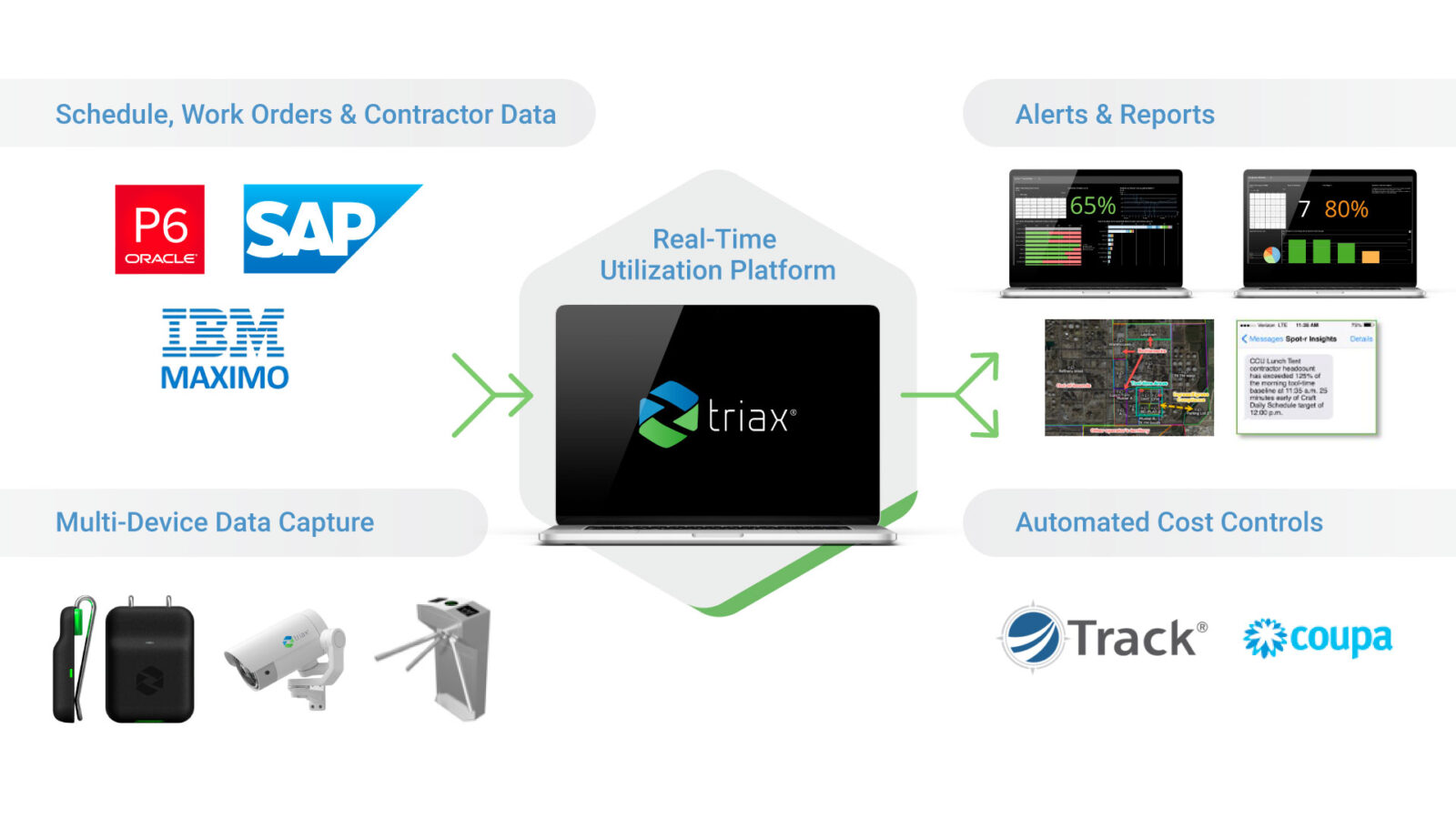

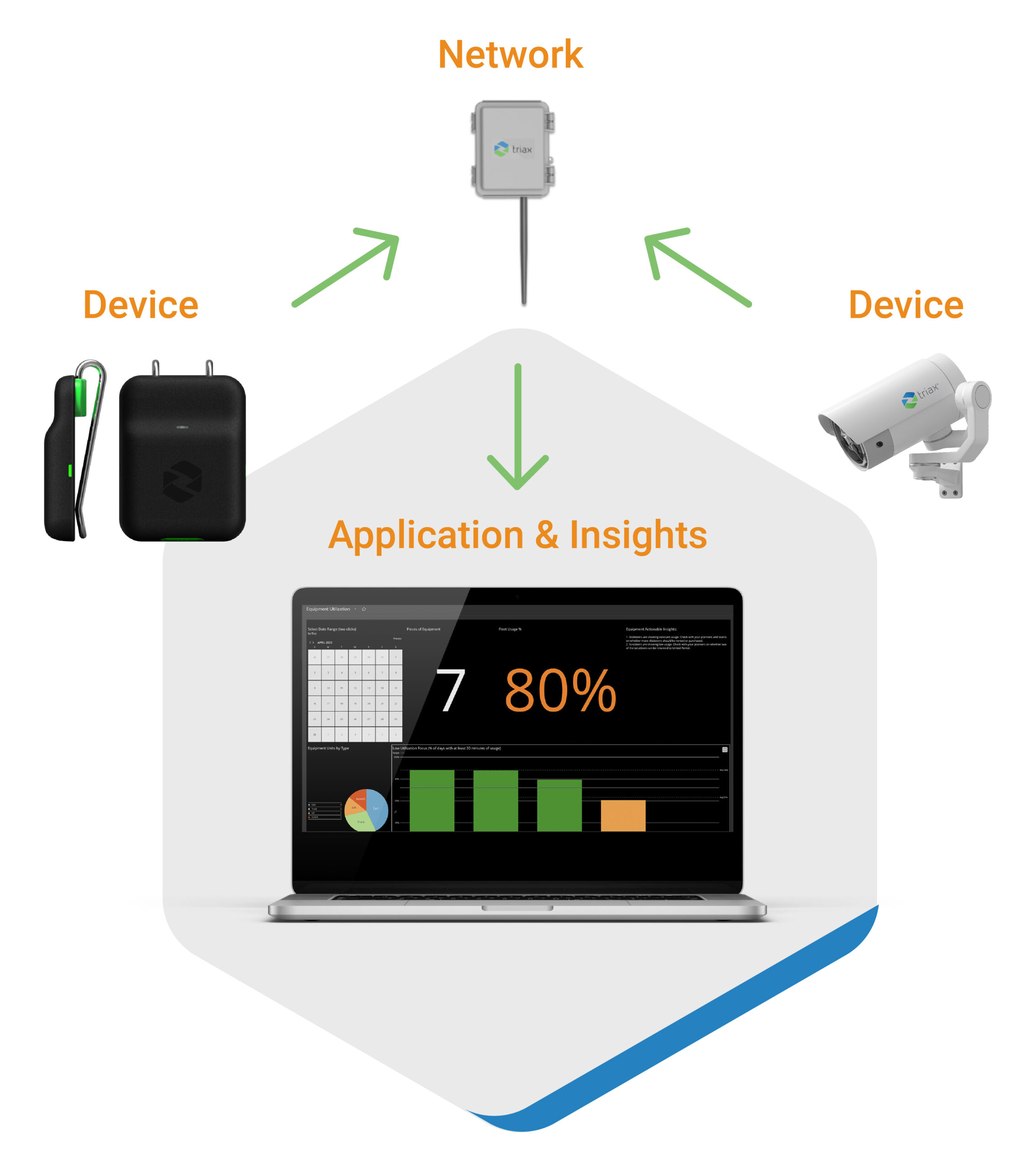

How Spot-r® Works

Across your worksite, a range of IIoT sensors collect data and transmit it into our cloud-based software across a standalone network independent from your internal IT infrastructure. You gain access to near real-time data about the work happening on your site. Analyze pinch points that decrease labor productivity, track your equipment utilization, and reduce time to safety in the event of an emergency. Control costs, speed up progress, minimize risk and waste, and discover a safer, more productive site with Triax.

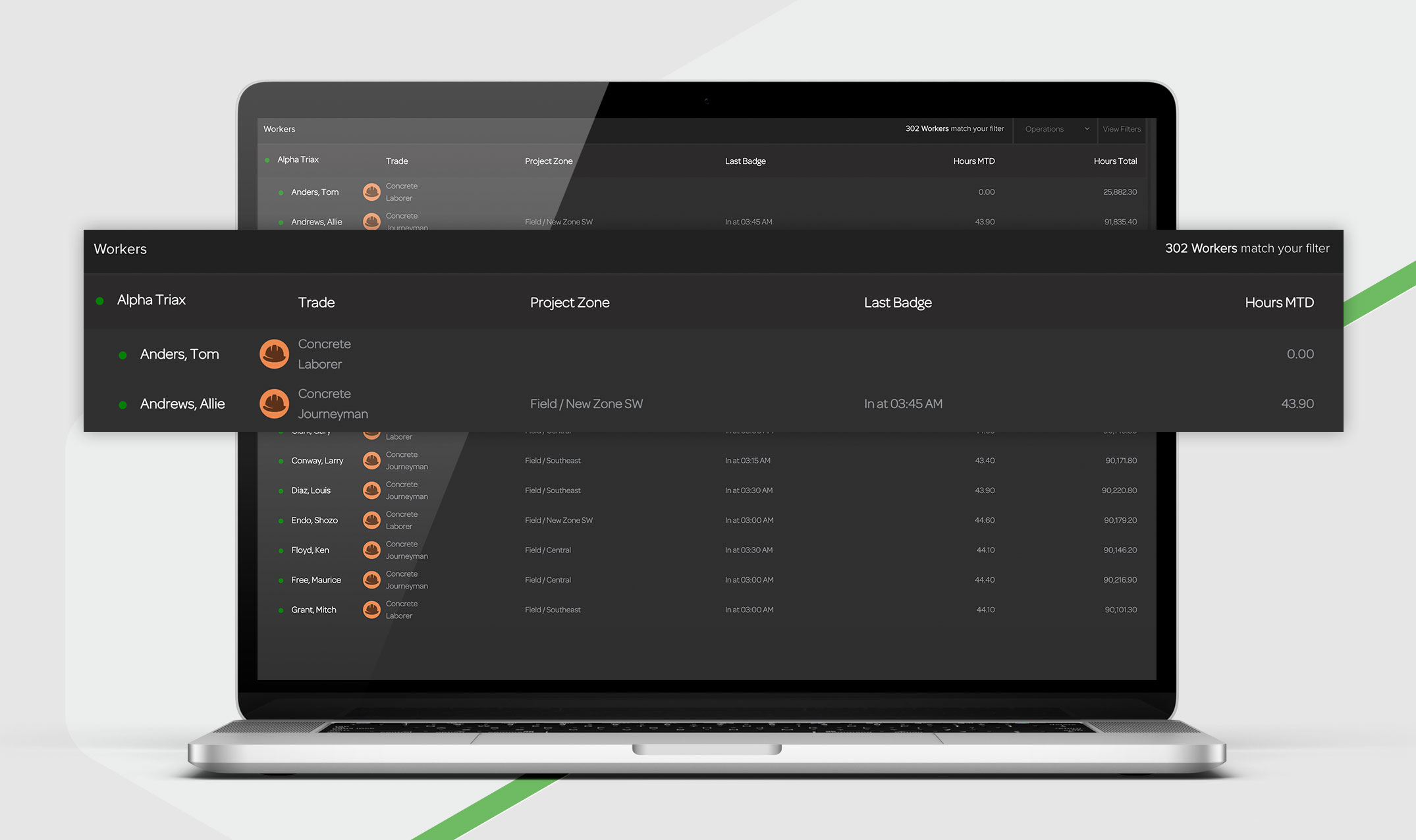

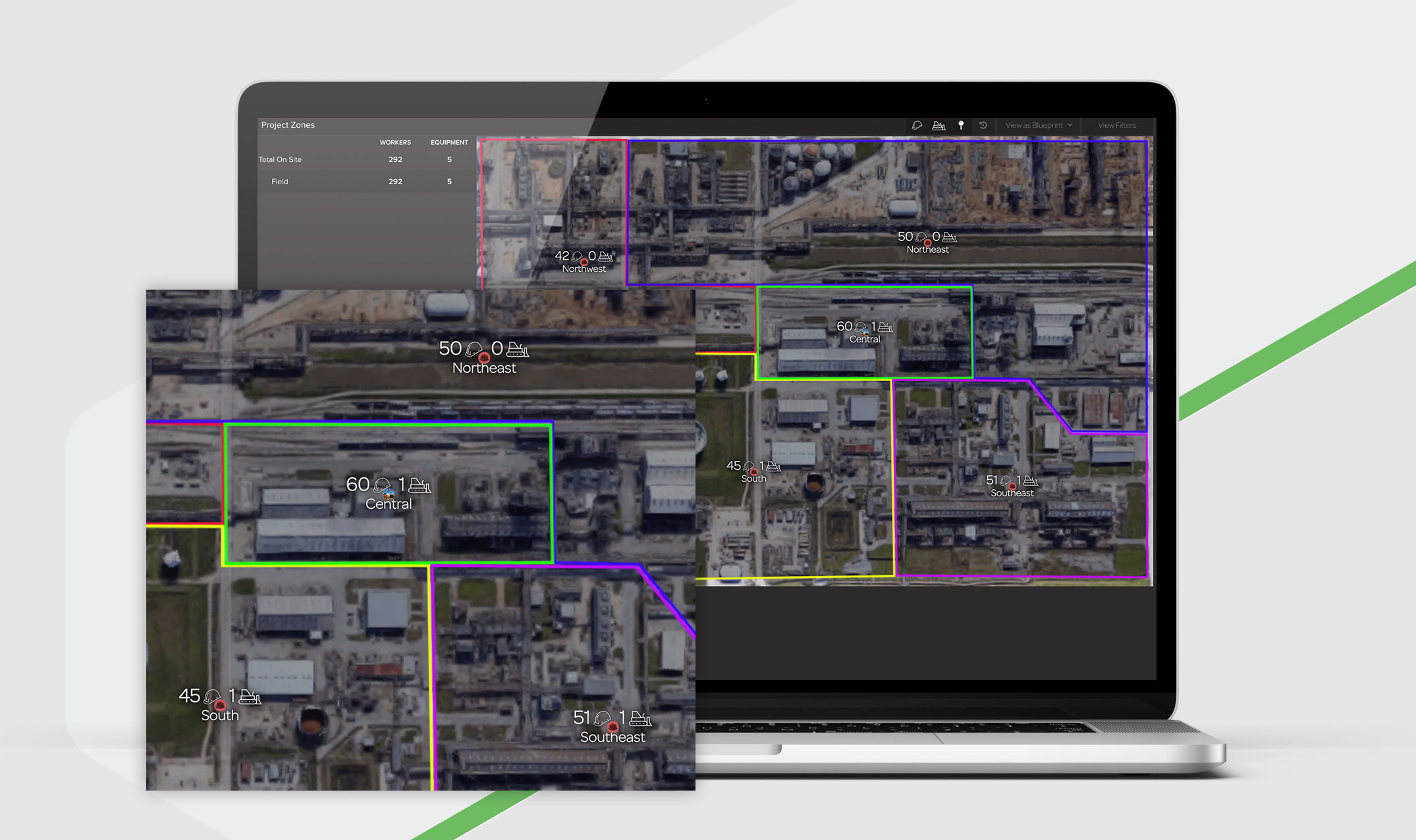

Explore the Spot-r Dashboard

Equipment utilization

Active work areas & volume over time

Crew performance

Wireless perimeter & divided worksites

Spot-r At A Glance

- Comprehensive real-time insights to help complex worksites run safely and efficiently

- Built to handle the biggest, most-complex worksites

- No dependency on client Wi-Fi, GPS, or existing IT infrastructure

- No offsite location data – we respect worker privacy

- Dedicated Triax site teams provide timely assistance every step of the way

- Rechargeable battery – months of use between charges

- Intrinsic Safety rated

- UL certified

- IP 66/67 rated

What can you improve with our IIoT platform?

Labor Productivity

Turn true worksite visibility into greater workforce productivity using real-time monitoring, collaboration tools, customized dashboards and advanced worksite analytics.

Equipment Utilization

Reduce costly and disruptive downtime while improving time on tool, increasing safety with automatic alerts, analyzing trends and more.

Emergency Management

Combine live alerts, site-wide notifications and real-time monitoring for emergency evacuations and falls to pivot faster in critical situations. Get valuable data to improve the effectiveness of safety and security procedures like evacuation and mustering.

Turnarounds

Decrease downtime on your worksite with the Spot-r features that optimize turnarounds. Our clients are able to leverage Spot-r data to pinpoint productivity bottlenecks, schedule communication, complete reporting, and improve the execution of site shutdowns.

Connected Worker

With Spot-r, no worker is an island. Harness full-process visibility, manage assets and ensure worker safety with real-time location and equipment monitoring, advanced analytics and more.

What is “Intrinsic Safety”?

Intrinsic safety (IS) is an engineering control for the most hazardous workplace environments. We engineered our IS devices to limit the possibility of ignition in environments where there are flammable gases or particles that present a dire hazard to workers. Being an IS IoT connected workplace solution, we are now able to connect all workers on site, no matter where they are working.

Hazardous environments requiring intrinsically safe devices can include oil refineries, mining, paint manufacturing, distilling, chemical plants, and spray booths. Flammable vapors and gases are the main safety issue in these industrial scenarios, and when they mix with oxygen in the air, they can establish an explosion-prone environment. Food processing factories, grain handling facilities, recycling operations, and even flour mills generate combustible dust, which is why these are hazardous locations too.

“With Spot-r, we’ve been able to streamline our operations, eliminate workflow bottlenecks, and measure our crews’ productivity levels. We’re excited about the availability of the Intrinsically Safe solution, so we can bring these benefits to sites that require IS controls in hazardous areas.”

Zack Steffen, Sourcing Transformation Leader – INVISTA

Explore how you can raise the bar on performance and safety with an IIoT productivity solution